Ground Investigation

Know the ground before you build on it. Igne provides end-to-end ground investigation services combining geotechnical insight, on-site testing, and deep analysis to de-risk design and support safe, efficient construction.

Combining geo-environmental expertise, ground investigation, specialist drilling, UXO risk mitigation, surveying and materials testing, Igne reduces risk, removes delays and keeps your programme on track.

Still exploring? Scroll on to see how Igne supports projects across the UK.

Know the ground before you build on it. Igne provides end-to-end ground investigation services combining geotechnical insight, on-site testing, and deep analysis to de-risk design and support safe, efficient construction.

Strength, compliance, performance. Igne’s UKAS-accredited materials testing service supports safe, high-quality construction through laboratory and on-site testing of concrete, asphalt, aggregates, and more.

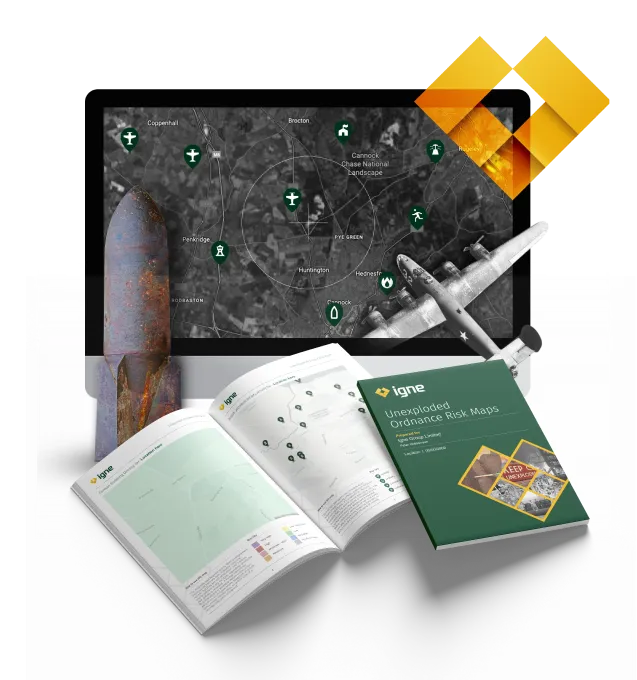

From risk assessments and non-intrusive surveys to on-site safety support and disposal, Igne helps you identify, manage and mitigate UXO risks so you can move forward safely, and with confidence.

From private water supplies and geothermal boreholes to deep data-gathering and advanced ground engineering, Igne’s specialist drilling services are designed to deliver: for homes, businesses, infrastructure and the environment.

Above ground, below ground, and beyond expectation. Our specialist survey teams deliver high-precision data for every stage of development from utility mapping and UAVs to topographical and measured building surveys.

Contamination risks, assessed and addressed. Igne’s geo-environmental specialists help you understand, evaluate and manage environmental risks: from desk studies and sampling to remediation advice and compliance support.

You have questions?

We have answers!

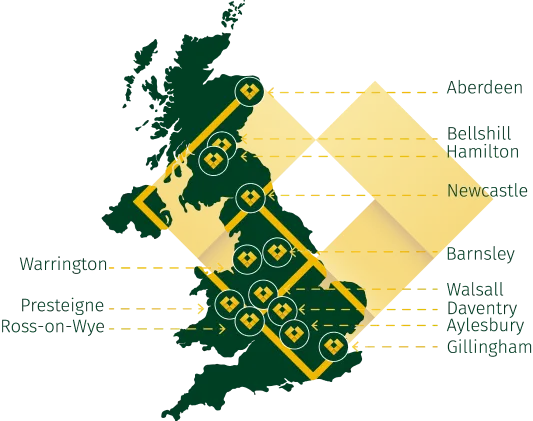

National Reach. Local Insight.

Proven Delivery.

Igne’s footprint spans the whole of the UK, giving clients confidence that wherever a project sits, our specialist teams are already within reach.

Our national scale is backed by deep local expertise - from complex geology and ground conditions to regional regulations, utilities and UXO risk, we understand it all. This integrated knowledge means faster mobilisation, fewer delays, consistent quality and one trusted partner delivering seamlessly across multiple sites and sectors. Reduce friction, cut costs and keep your projects moving with clarity, certainty and control - choose Igne.

Engineers and

on-site operatives

Scientists and

laboratory technicians

Planning and

analytical staff

Administration and

management

Advanced Plant. Decades of Expertise. A Standard of Operational Excellence You Can Trust.

Our teams operate with precision, consistency and discipline, supported by a fleet engineered for performance in the most demanding environments. Every project benefits from rigorous planning, skilled delivery and the confidence that work will be completed safely, efficiently and exactly to specification.

Our fleet is made up

of 242 vehicles

Litres

554,540 litres of hot beverages consumed by our drilling teams

This equates to nearly a quarter of the volume of a 50m swimming pool worth of tea. In fact, our drillers drink their own body weight in tea every 23 days.

Our drilling teams have drilled over 792km since 1988

The same as drilling the elevation of Everest nearly 90 times

Which is equivalent to drilling 82% of the distance from Land's End to John o'Groats as the crow flies. If travelling by road the lads would be on the outskirts of Sunderland - effectively they've drilled all the way home!

Customers

Today’s customers want actionable insight and critical services available on time, on budget, on scope.

The best businesses in their respective fields were brought together as Igne to deliver integrated geo-environmental, ground investigation, surveying, materials testing, unexploded ordnance risk mitigation, and specialist drilling services.

Years' combined experience

Check your site’s UXO risk instantly,

Covers every threat from air raids to military targets.

No cost. No waiting.

Just intelligent, location-specific insight in seconds.

When the Second World War ended, Britain breathed a collective sigh of relief. The threat of invasion had passed, the blackouts lifted, and communities…

Ramblers have been warned about UXO on public paths now reopened after the fires on Langdale Moor. Igne EOD experts are on standby...

The latest ‘volunteer’ for the now multi-award-winning Staff Spotlight feature is Steven Osborne, Igne’s new Operations Manager for Materials Testing …

Discover why high-water users and developers should consider private water supply. Igne designs and drills sustainable boreholes for resilience and control…